Equipment used for drilling in the oil and gas industry experience some of the harshest and most demanding conditions in terms of pressure, temperature, and wear. As a consequence, specialized materials such as cemented carbides, diamond, and specialty alloys are necessary to provide the performance and product life that customers require. Hard and SuperHard materials are at the core of iAlloys’ offerings. Our organization includes a diversified group of companies, including the first manufacturer in China to produce a synthetic diamond. We are a global leader in specialty tungsten and metallic powders with state-of-the-art carbide component manufacturers all of which target specific product segments.

Download Catalog

iAlloys’ radial bearings incorporate hard and superhard materials to minimize the extreme wear conditions experienced in downhole applications. Manufactured to customer dimensional specifications and lined with carbide or TSP on critical wear surfaces, our radial bearings are engineered to increase ROP, allow tighter radius turns, and extend run life.

Carbide and specialty metal components and assemblies for shielding and wear resistance

Nozzles and sleeves for drill bits

Spherical, conical, ballistic, chisel, and gauging configurations for drilling applications.

Fixed cutter bit inserts utilizing the latest non-planer interface designs for drilling in oil and gas exploration.

Domed PDC Inserts for Oil and Gas Drills, Hammer Bits and Gaging

Inserts for soft formation drilling, gauging, and wear applications

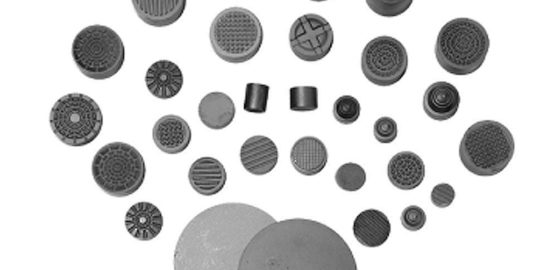

Wide range of carbide grades and surface geometries, engineered for PDC sheer cutters

Synthetic diamond grit for oil and gas drills and components

Downhole drilling stabilizers in multiple configurations including straight, spiral, integral, sleeve, and non-magnetic manufactured to customer specifications.